A Tapestry of Innovation: How Interchangeable Feet Democratized Sewing

The rhythmic clatter of a sewing machine – a sound synonymous with creativity, resourcefulness, and the quiet industry of countless homes and small businesses. We often marvel at the machines themselves, the cast-iron behemoths or the elegant, streamlined models of the early 20th century. But have you ever paused to consider the seemingly small, yet revolutionary, innovation that truly unlocked their potential: the interchangeable foot? Before their advent, sewing was a more constrained pursuit, a skill often passed down within families, its possibilities limited by the inherent capabilities of a single, fixed attachment. The rise of interchangeable feet wasn't just a technical advancement; it was a democratization of crafting, a liberation of creative expression.

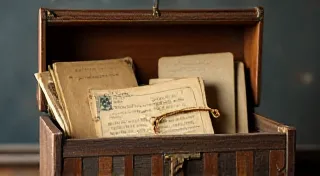

My grandmother, Elsie, was a master seamstress. I remember, as a child, watching her transform scraps of fabric into quilts that told stories. She owned a Singer 201, a robust machine that hummed with quiet power. What always fascinated me wasn’t just the machine itself, but the small box of metal feet she kept meticulously organized. Each one, she's explained with a twinkle in her eye, had a purpose. A buttonhole foot for intricate detailing, a gathering foot for ruffles and pleats, a zipper foot for precise closures. Seeing her effortlessly switch them out, adapting the machine to each task, felt like witnessing a subtle act of magic. It underscored a crucial point: the sewing machine wasn't just a tool, it was a platform for limitless ingenuity.

The Pre-Foot Era: A More Limited Landscape

Early sewing machines, while groundbreaking inventions in their own right, were notoriously inflexible. Elias Howe, Isaac Singer, and others initially conceived of machines with fixed attachments – a single 'face' that performed a single function. While these early models revolutionized clothing production in factories, their capabilities were significantly curtailed for the home sewer. Think of it: needing to make a set of buttonholes required incredibly precise, painstaking manual work, or relying on a skilled professional. Complex tailoring projects were often beyond the reach of the average home crafter. The machine's potential remained largely untapped, confined by the limitations of that fixed face. These machines were a wonder, certainly, but they were also restrictive.

The very notion of easily swapping out components was relatively new to domestic machinery. While some industrial machinery had experimented with changeable parts, the concept of individual, standardized feet for sewing machines didn't immediately take hold. The initial focus was on refining the core sewing process – the stitch itself – rather than expanding its possibilities. This period highlights a crucial difference between industrial and domestic applications: factories prioritized efficiency and volume, while home sewers craved versatility and adaptability.

The Dawn of Interchangeability: A Seed of Creative Possibilities

The shift began gradually. Different manufacturers experimented with various attachment designs. Early patents hinted at the potential for greater flexibility. Singer, a dominant force in the sewing machine market, played a significant role in popularizing the concept. While early "attachments" were often proprietary and somewhat cumbersome, the idea was firmly planted. Gradually, more standardized designs emerged, allowing feet from different manufacturers to work on similar machines, albeit sometimes with varying degrees of compatibility.

This wasn’t solely a matter of convenience; it was about opening up new avenues for creativity. Suddenly, a home sewer could create more elaborate garments, experiment with different fabrics and techniques, and even start small tailoring businesses. The machine became a partner in the creative process, a tool capable of responding to a wide range of projects. Small businesses, particularly those run by women, flourished as the ability to quickly and easily produce items expanded their opportunities.

Craftsmanship and Collectibility: Recognizing the Legacy

The antique sewing machine feet themselves are fascinating objects of craftsmanship. The intricate designs, the precision of the machining, the patina of age – all speak to a bygone era of meticulous manufacturing. These aren’t mass-produced, disposable items; they are durable, well-made tools built to last. Many are stamped with the manufacturer's logo, providing a tangible link to the history of the sewing machine industry.

Identifying antique sewing machine feet can be a rewarding pursuit for collectors and enthusiasts. Variations in design often reflect technological advancements and evolving sewing techniques. A simple buttonhole foot from the 1880s will look quite different from a more sophisticated, adjustable model from the 1920s. The materials used also provide clues about the foot's age – early feet were almost exclusively made of cast iron or steel, while later feet might incorporate other metals or even plastic components.

Beyond the Basics: Specialized Feet and Their Stories

The range of specialized feet available is astonishing. Gathering feet for creating ruffles and pleats, blind stitch feet for invisible hems, edge stitching feet for decorative finishes – each one was designed to address a specific sewing challenge. Some feet are quite common, while others are rarer and more sought-after by collectors. These feet aren't just tools; they're windows into the diverse needs and aspirations of home sewers throughout history. Imagine the countless garments, quilts, and other creations made with the assistance of these humble attachments.

A gathering foot, for example, was invaluable for creating intricate drapery and ornamentation. A darning foot, allowing for the repair of worn areas in fabric, extended the lifespan of cherished garments. Each foot tells a story – a story of ingenuity, resourcefulness, and the enduring human desire to create.

A Lasting Impact: Democratizing the Craft

The introduction of interchangeable sewing machine feet wasn’t just a technological advancement; it was a social one. It empowered individuals, particularly women, to pursue their creative passions and even build small businesses. It democratized the craft of sewing, making it more accessible and versatile than ever before. The quiet hum of a sewing machine, coupled with the click of a foot being changed, became the soundtrack to countless stories of creativity and resilience.

Looking back, it's easy to appreciate the profound impact of this seemingly small innovation. The ability to adapt the sewing machine to a wide range of tasks unlocked its true potential, transforming it from a specialized industrial tool into a cherished companion for home sewers around the world. The legacy of those early pioneers – the inventors, the manufacturers, and the countless home crafters who embraced this technology – continues to inspire us today.