Whispers from the Workshop: Deciphering Markings & Maker's Secrets on Antique Sewing Machine Feet

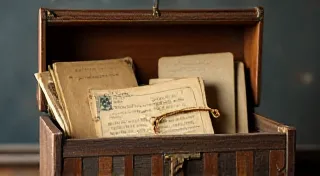

There's a quiet dignity to an antique sewing machine foot. More than just a small piece of metal, it’s a tangible link to generations of makers, a silent witness to countless garments and cherished memories sewn into being. Holding one in your hand, you can almost hear the hum of the machine, the rhythmic click of the needle, and feel the focused energy of its user. But beyond the tactile connection, these feet hold secrets – whispers from the workshop, if you know how to listen. This guide explores the fascinating world of identifying antique sewing machine feet, uncovering the makers, the dates, and the stories embedded within the metal.

My own fascination with these diminutive tools began innocently enough. I inherited my grandmother’s Singer 66-13, a beautiful machine that had seen decades of service. While cleaning and restoring it, I noticed the incredible variety of feet included – a zig-zag foot, a buttonhole foot, a darning foot – each seemingly unremarkable on its own, yet each playing a vital role in a broader creative process. It wasn't long before I started to wonder: Who made these? When were they made? What else can they tell me about the machine’s history and the woman who used it?

The Rise of the Sewing Machine & Foot Innovation

The mid-19th century witnessed a revolution – the dawn of the practical sewing machine. Figures like Elias Howe and Isaac Singer are often credited with this breakthrough, but the subsequent decades saw a whirlwind of innovation, particularly in attachments and accessories. Early sewing machines were remarkably basic, and the ability to perform different tasks relied heavily on interchangeable feet. This spurred a competitive landscape, with manufacturers constantly seeking to improve functionality and design. The late 1800s and early 1900s were a golden age for sewing machine attachments, and the variety of feet available reflects this period of intense creativity.

Initially, many feet were made by the same companies that manufactured the machines themselves – Singer, Wheeler & Wilson, Grover & Baker – but as the market grew, smaller, specialized manufacturers emerged. These smaller shops often focused on producing unique or high-quality feet, catering to specific sewing needs or offering specialized embellishments.

Deciphering the Markings: A Detective's Guide

Identifying antique sewing machine feet relies heavily on careful observation and a bit of detective work. Markings, however small or faded, are your primary clues. Here's a breakdown of what to look for:

- Maker's Marks: The most obvious, but often the most challenging. Look for names like "Singer," "Wheeler & Wilson," "Grover & Baker," "Willcox & Gibbs," or smaller, less common names. These are often stamped into the metal, sometimes subtly and other times with more prominence.

- Patent Numbers: Many feet were patented, and the patent number stamped on the foot can provide a crucial date range. Patent records are publicly available online and can be a fantastic resource for further investigation.

- Style and Design: The overall design of the foot can offer clues. Certain design elements were characteristic of specific manufacturers or time periods. For example, the shape of the presser foot, the style of the shank (the part that attaches to the machine), and the type of hinge used can all be indicative of origin.

- Material and Construction: Early feet were primarily made of brass or steel. Later feet might incorporate more advanced materials like stainless steel or aluminum. The quality of the finish and the precision of the construction can also provide clues about the manufacturer and the intended market.

The challenge is that markings can be worn, obscured by rust, or simply too small to see without magnification. A jeweler's loupe is an essential tool for any serious antique foot collector. It's also important to remember that feet were often swapped and replaced over time, so a foot found on a particular machine might not actually be original to that machine.

Common Manufacturers & Their Characteristics

While a comprehensive list would be extensive, here’s a glimpse into some of the key players and their typical characteristics:

- Singer: Likely the most common, Singer feet are generally well-made and identifiable by the "Singer" mark. Early Singer feet often have a distinctive triangular shank.

- Wheeler & Wilson: Known for their robust and reliable machines, Wheeler & Wilson feet are typically stamped with the “W&W” mark.

- Grover & Baker: Grover & Baker feet are recognized by the “G&B” mark and often have a more ornate design.

- Willcox & Gibbs: These feet are stamped with “W&G” or “Willcox & Gibbs” and are known for their quality and durability.

- Household: A lesser-known maker, Household feet are often found on older machines and can be quite collectible.

Beyond Identification: Appreciation & Preservation

Identifying antique sewing machine feet isn't just about ticking off a checklist of manufacturers and dates. It’s about appreciating the craftsmanship, the ingenuity, and the history embodied within these small objects. Each foot represents a moment in time, a connection to a world of skilled artisans and dedicated makers.

Preserving these pieces is crucial. Careful cleaning (avoiding harsh chemicals) and proper storage can prevent further deterioration. Understanding their purpose and original function can also inform restoration efforts. While some collectors strive for originality, others appreciate the patina of age and the stories etched into the metal.

Holding a correctly identified foot, understanding its history, and imagining the garments it helped create is a rewarding experience. It allows us to connect with the past in a tangible way, honoring the legacy of those who came before us and appreciating the enduring power of a simple sewing machine and its small, but mighty, feet. They are more than just tools; they are whispers from the workshop, waiting to be heard.